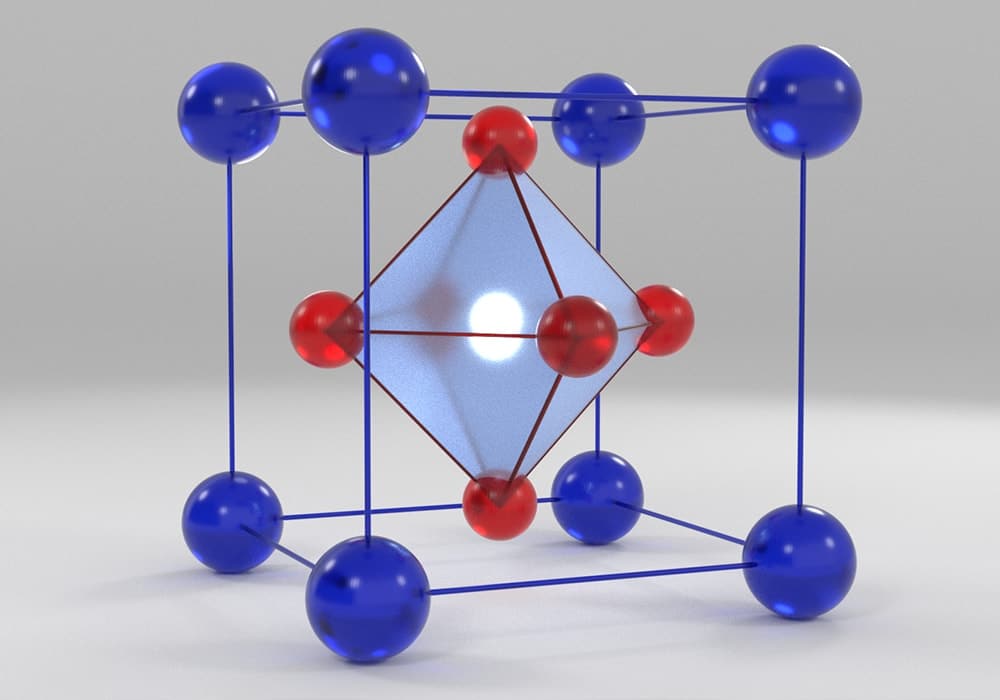

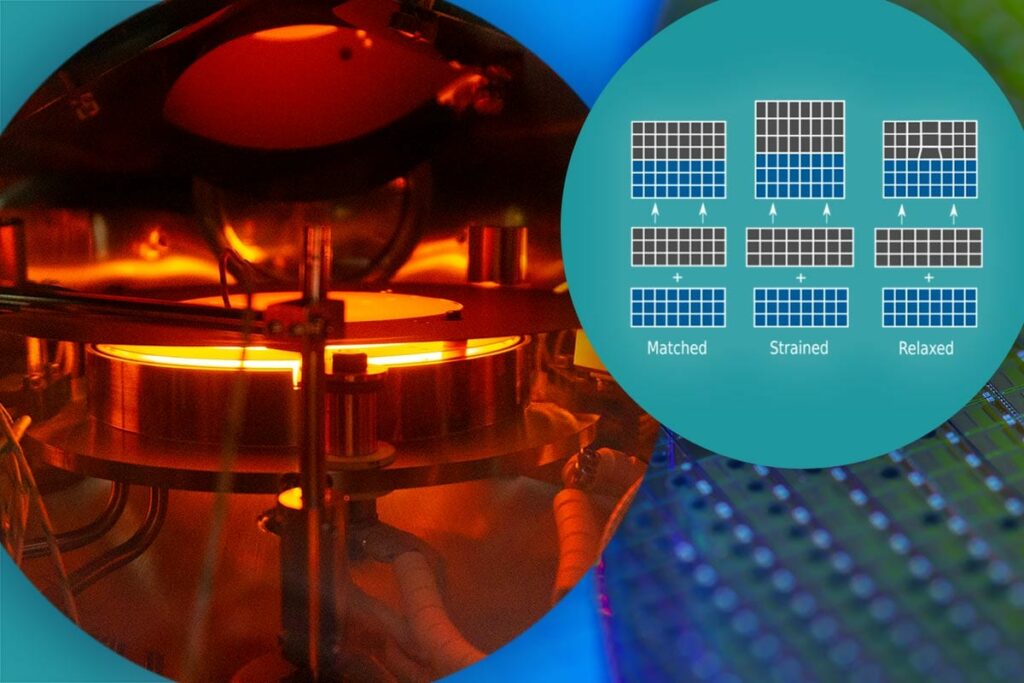

What are Perovskite Solar Cells and how are they made?

Compared to other photovoltaic technologies, perovskite solar cells are currently showing impressive rates of performance improvement. We take a look at the fabrication process and useful systems for deposition.

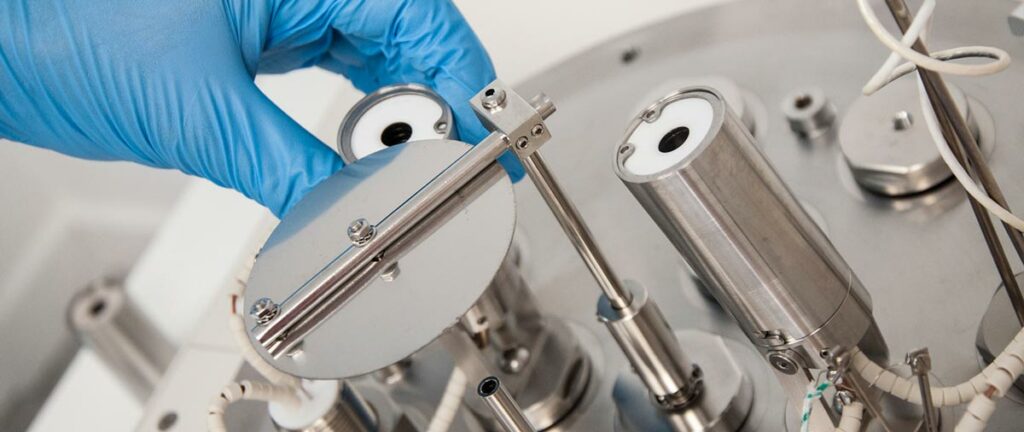

Load lock & fast entry chambers

A guide to available variations from Moorfield

Substrate adhesion of sputtered films

An introductory explanation of substrate adhesion, and how this can be improved.

Graphene soft-etching with the nanoETCH

Moorfield graphene soft-etching technology allows for the controlled removal of graphene and 2D materials, without cross-linking photoresists that can lead to residual contamination that affects device performance.

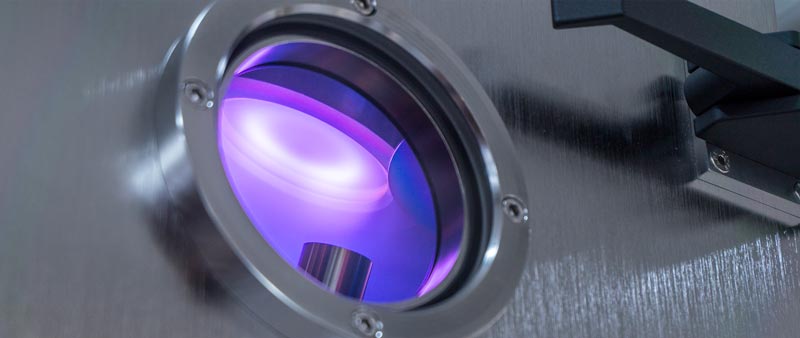

Confocal magnetron sputtering

Confocal magnetron sputtering is now routinely employed for the production of excellent uniformity, multi-layer films by magnetron sputtering. This application note describes the technology, and explains the principles behind it.

Source selection for thermal evaporation

Thermal evaporation sources A thermal evaporation (TE) component typically consists of power supply rods, usually fashioned from thick copper, mounted to feedthroughs that allow transmission of current from an air-side power supply network through to a high-vacuum process chamber. Clamped between the power legs is a resistive support on which the material to be evaporated […]

Magnetron sputtering

Magnetron sputtering is a versatile technique suited to a wide range of materials – and provides excellent coating-substrate adhesion.

Low temperature evaporation

The basics of Vacuum Evaporation Low temperature evaporation is a recent development in the field of vacuum evaporation. Traditional vacuum evaporation methods work, essentially, by heating materials to high temperatures. This is required for common thin-film evaporants so that they are vapourised from a source. The evaporants then move up through a process chamber to […]

Thermal evaporation

Thermal evaporation is the most straightforward physical vapour deposition (PVD) technique, in terms of both mechanism and system configuration. The method is suitable for depositing a range of materials, primarily metals.

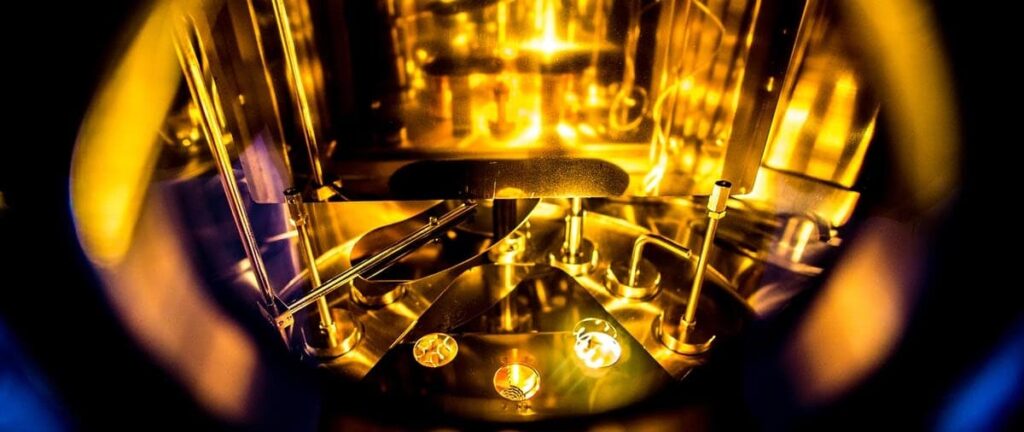

Electron-beam evaporation

Like all evaporative physical vapour deposition (PVD) methods, electron-beam evaporation (also known as e-beam evaporation) involves heating a material under vacuum conditions (typically in the 10-7 mbar region, or lower). This in-turn releases a vapour that moves up through a process chamber and coats a substrate at the top.