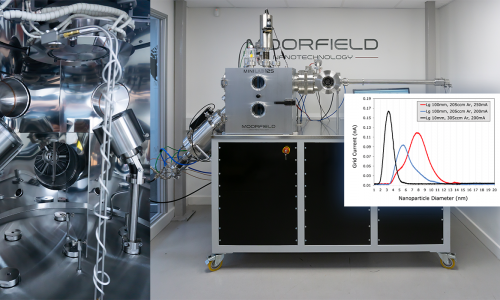

Plasma etching

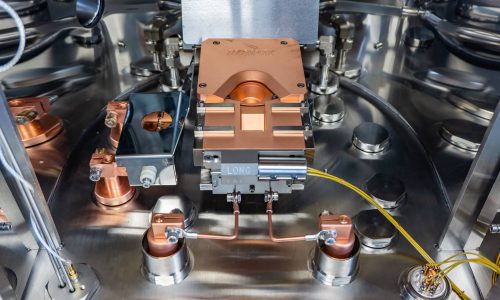

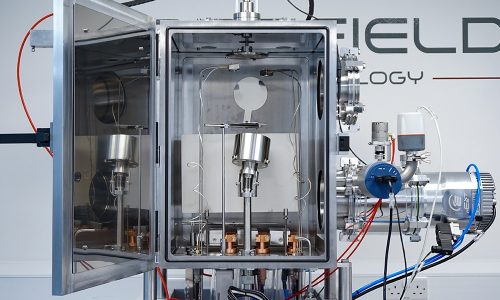

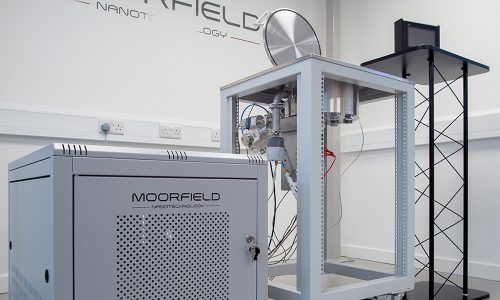

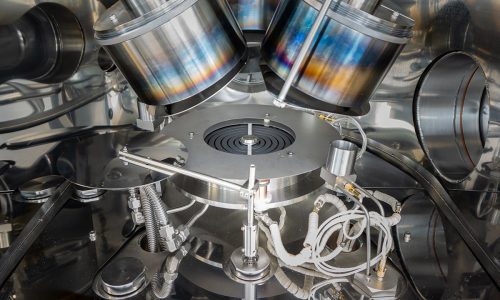

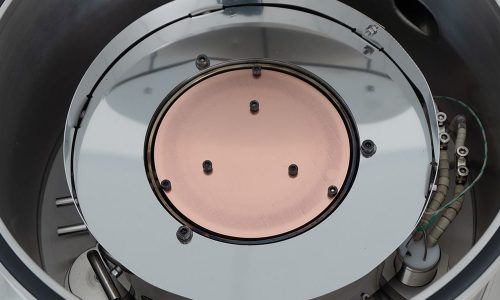

Plasma etching technology from Moorfield is used for for Soft Etching of sensitive materials, reactive ion etching (RIE) and for substrate cleaning. The technology is available packaged into dedicated nanoETCH tools or in combination with other hardware inside larger MiniLab process chambers and load-locks.