This has allowed nanoETCH and MiniLab tools fitted with reactive ion etching (RIE) hardware to be used for removal of a wide range of materials far beyond those structured on carbon — for which the etching range was originally created more than 10 years ago.

In recent times, we have worked with academic and industrial partners to develop and test this novel technology for a variety of cutting-edge applications.

h-BN Etching

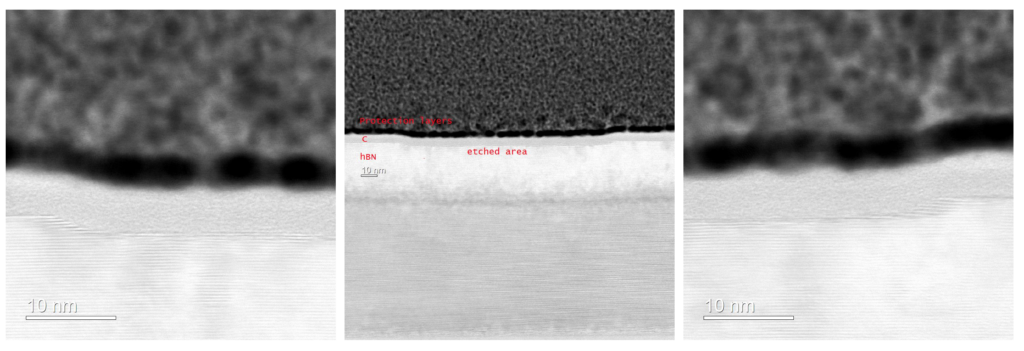

Researchers working in the NANOMADE section at the Department of Physics, DTU, used a Moorfield MiniLab 026 system to etch pits with controlled depths in multi-layer h-BN samples using SF6 as the etchant gas. This allowed for the exposure of layer sidewalls with shallow angles, ideal for the formation of electrical edge contacts to, e.g., embedded layers of other 2D materials. Transmission electron microscopy (TEM) analysis of a representative sample is shown below.

The system used for this work was a Moorfield MiniLab 026 tool fitted with Soft Etching hardware with automatic gas and high-resolution pressure control. The tool was integrated within a supporting glovebox allowing for pre- and post-process sample handling within a protective inert atmosphere.

SiO2 Etching

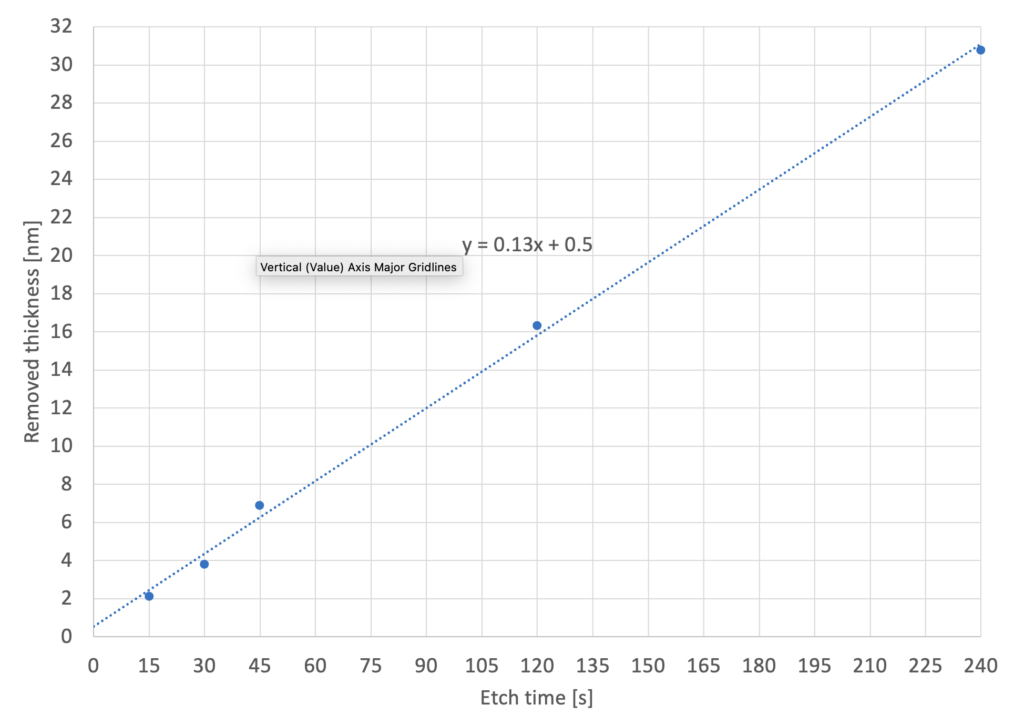

An industrial partner used a purpose-designed nanoETCH system to remove various thicknesses of an SiO2 film, using a process gas recipe including CHF3 as the etchant mix. Importantly for the application, they were able to obtain low and controlled etch rates by changing process conditions including the applied RF power — a key feature of the Moorfield Soft Etching technology is that precisely controlled low RF powers are achievable. A plot showing typical etch rates during processing is shown below.

The system used was a Moorfield nanoETCH tool equipped with Soft Etching hardware and process modifications including automatic purge routines and chamber cleaning procedures. nanoETCH tools offer capabilities of large, complex systems but in a compact package suitable for benchtop location.

More Information

For further information on any of the above or for a quotation, please contact us today.