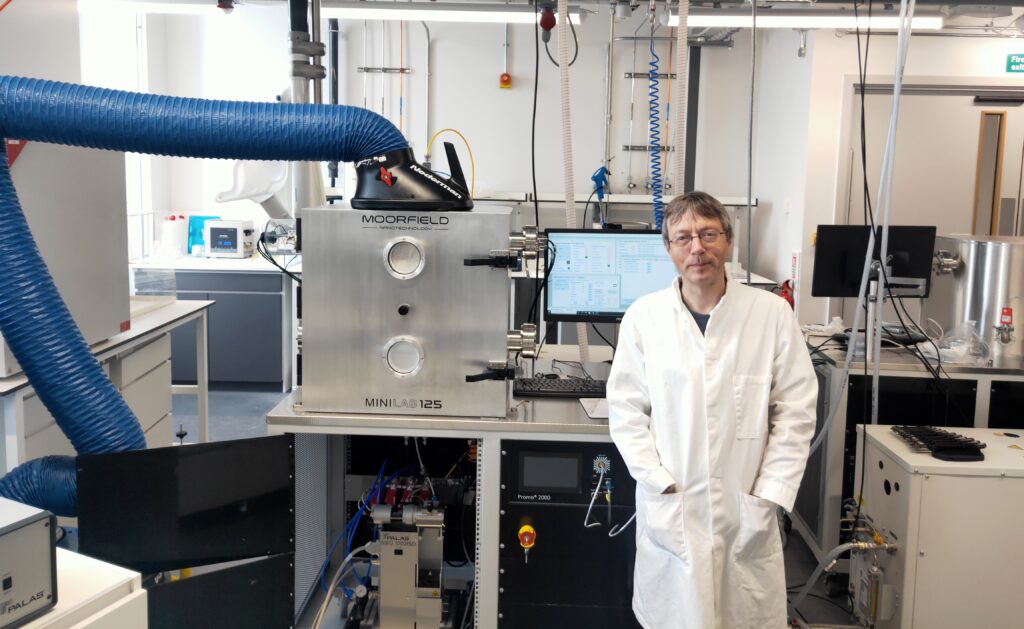

For this, the technology implements low power plasmas (< 10 W) with fine power control (down to 10 mW), allowing material removal without collateral damage. This application note demonstrates the use of soft-etching technology implemented via a Moorfield nanoETCH tool as part of the successful production of a graphene Hall bar device.

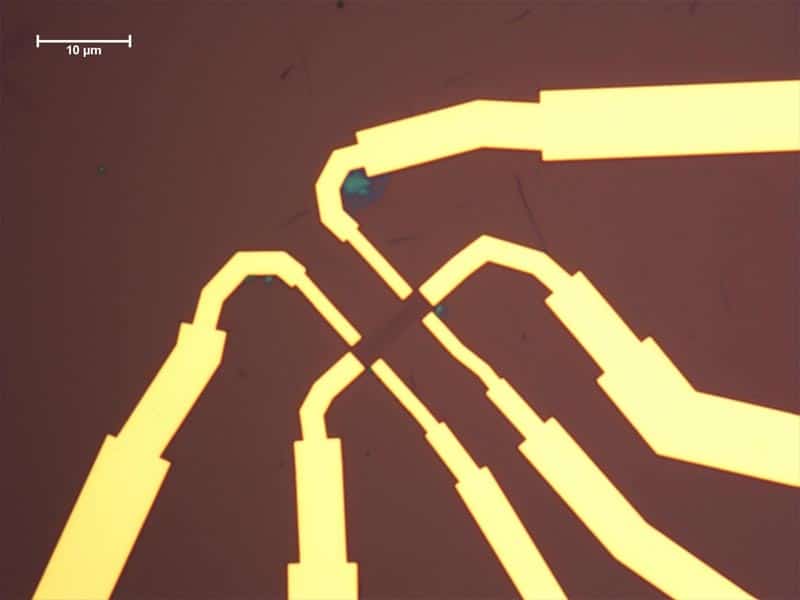

Photolithography & soft-etching:

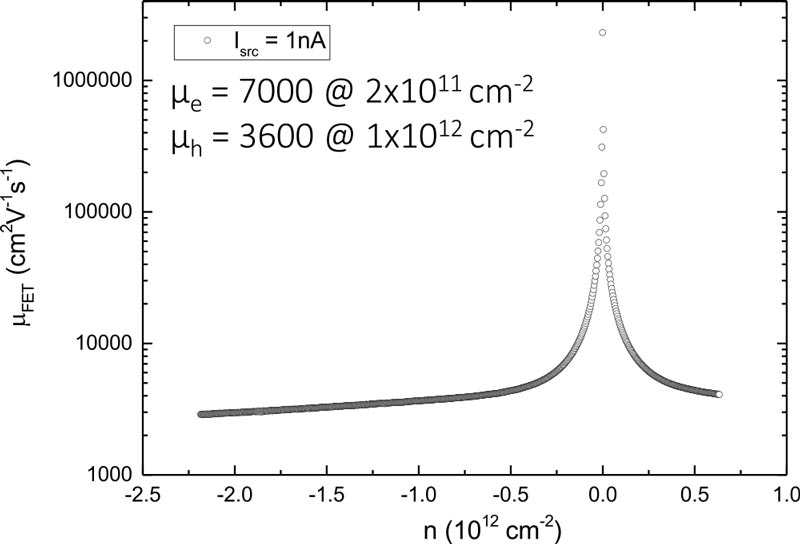

Device performance

CVD graphene devices fabricated using the Moorfield nanoETCH have demonstrated high electron mobilities in excess of 7000 cm2/(Vs) at room temperature and negligible doping (see figure 1). In part, this is possible due to the soft-etching process employed that allows for the complete removal of unwanted graphene while leaving negligible residue on the top surface of remaining material that forms the functional part of the device.

Acknowledgements

All data supplied by Prof. Monica Craciun and Prof. Saverio Russo at the University of Exeter, UK.