How it works

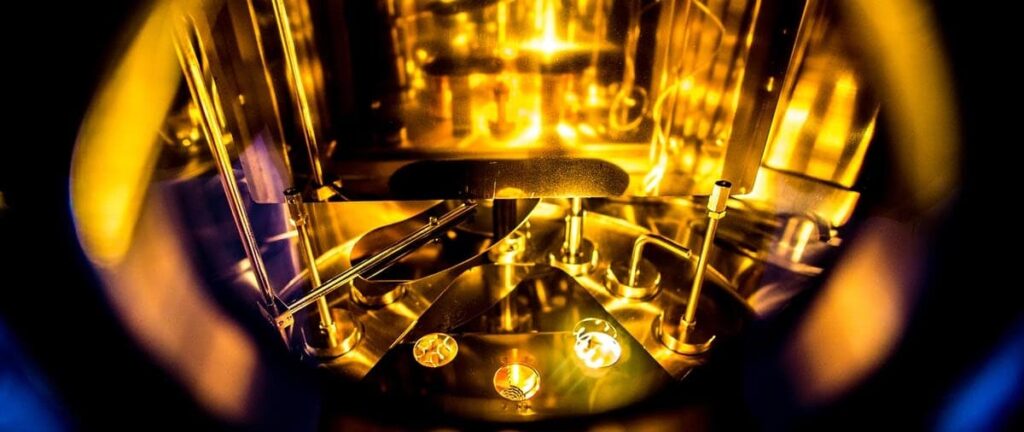

To start, substrates are supported at the top of a process chamber above a component on which the evaporant is supported (known as the ‘source’).

The resistance of the source leads to heating as the current passes through, which, in turn, heats the supported evaporant. With sufficient temperature, and under vacuum, the evaporant either evaporates or sublimes (depending on its physical properties). This releases vapour that moves up through the process chamber and coats the substrate. Thermal evaporation is carried out under vacuum conditions to allow for high-vapour pressures for a certain temperature.

Thermal evaporation is suitable for many metals, including Chromium and Gold for contact electrodes. However, it is not suitable for depositing materials with very high vapourisation temperatures. This rules out the technique for some applications.

For best results…

Sources are usually made from tantalum, molybdenum, or tungsten (i.e., metals tolerant to the high temperatures involved). Sources come in different forms such as boats, baskets, filaments, and coated rods. The form used depends on the properties of the evaporant and the process application.

For best results, thermal evaporation should be carried out under high-vacuum conditions, typically in the 10-7 mbar region, or lower. Any chamber contamination can be easily incorporated into deposited films, affecting their properties.

Evaporation techniques are line-of-sight, with evaporant vapour moving in straight lines between the source and the substrate. As such, they provide highly anisotropic coating, useful for, among others., liftoff applications.

Moorfield systems for thermal evaporation

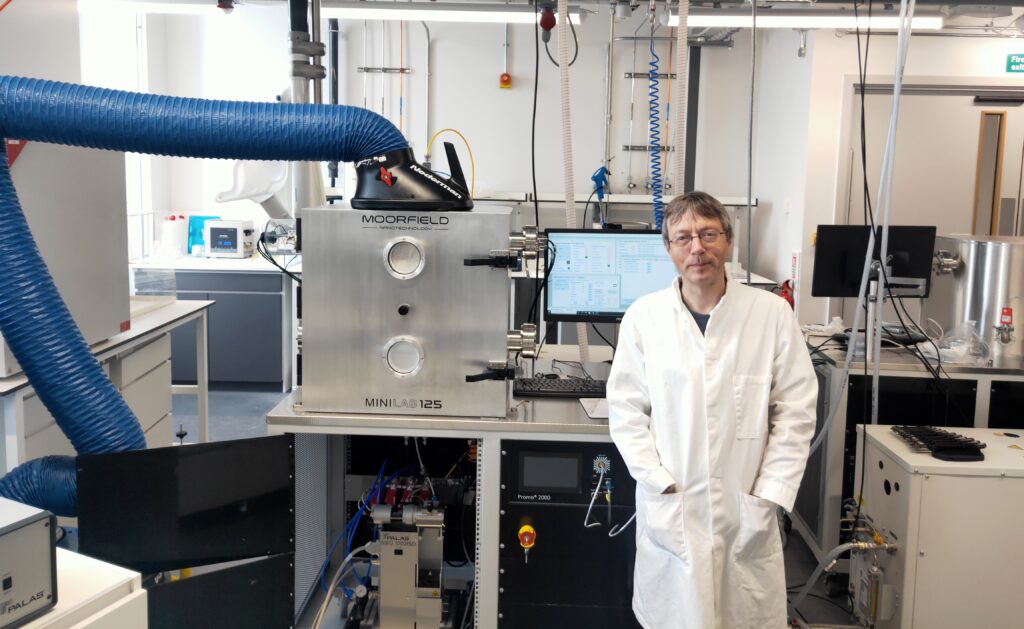

MiniLab systems

Flexible, modular PVD systems for high- quality R&D and pilot-scale production.

View systems

nanoPVD-T15A systems

A benchtop, RF and DC magnetron sputtering system for metals and insulating materials.

View system