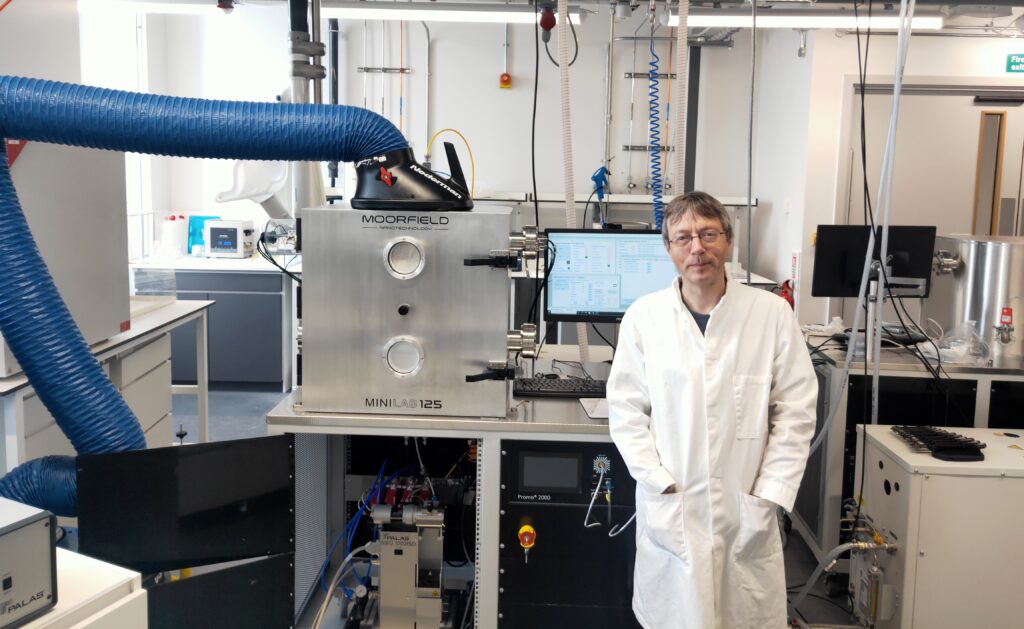

Electron-Beam Evaporation

Electron-beam (e-beam) evaporation is a type of physical vapour deposition in which a material to be deposited is heated to a temperature at which it evaporates, by bombardment with a beam of electrons.

- Products: MiniLab deposition systems | Components & parts

- Knowledgebase: Electron-Beam Evaporation

Thermal Evaporation

Thermal evaporation is a common, straightforward means of thin film deposition typically used to deposit metals. Materials are heated, under vacuum, to temperatures at which they evaporate or sublime

- Products: MiniLab deposition systems | Components and parts

- Knowledge base: Thermal Evaporation

Low-Temperature Evaporation

Low-temperature evaporation, or LTE, is ideal for deposition of high vapour-pressure materials such as organic compounds used in OLED and photovoltaic technologies.

- Products: MiniLab deposition systems | Components and parts|

- Knowledge base: Low-Temperature Evaporation

Magnetron Sputtering

In sputtering, deposition material is ejected from a target surface through bombardment by plasma ions. The technique is suited to high melting-point materials and provides excellent coating-substrate adhesion.

- Products: nanoPVD-S10A benchtop sputtering system | MiniLab deposition systems | Components and parts

- Knowledge base: Magnetron Sputtering