Metal-insulator-metal diodes based on alkyltrichlorosilane self-assembled monolayers

This paper reports the fabrication metal-insulator-metal (MIM) diodes based on alkyltrichlorosilane self-assembled monolayers (SAMs) and investigation of the effects of parameters such as alkyl chain length on the electronic properties, for applications in high speed electronics.

PVD techniques

Moorfield are experienced in all common PVD techniques and can supply systems with fully-integrated component sets. Standalone components also available.

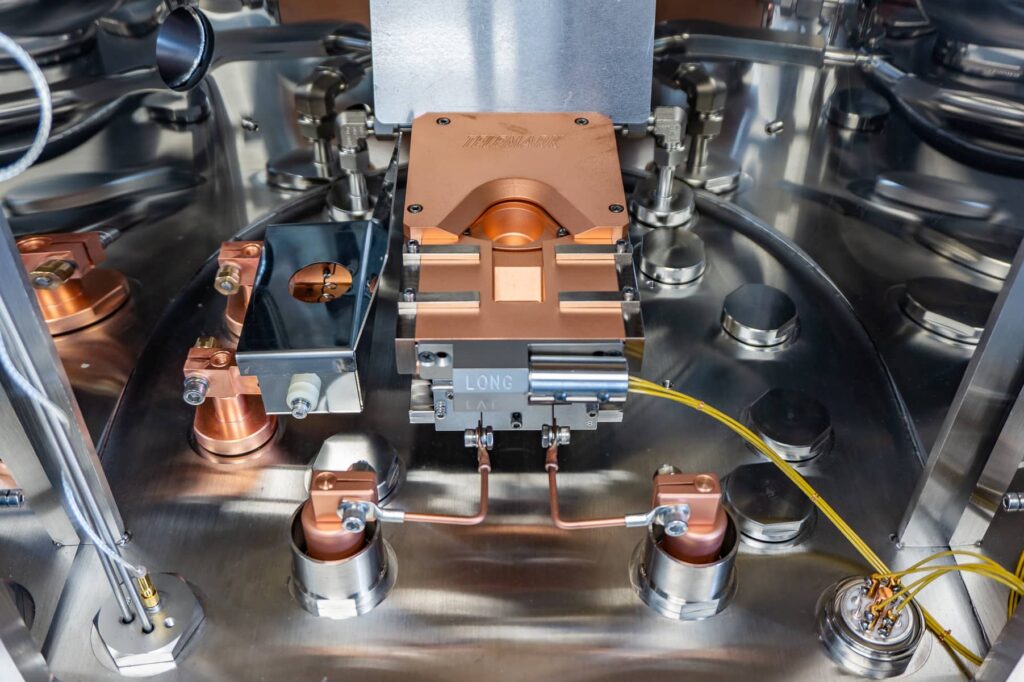

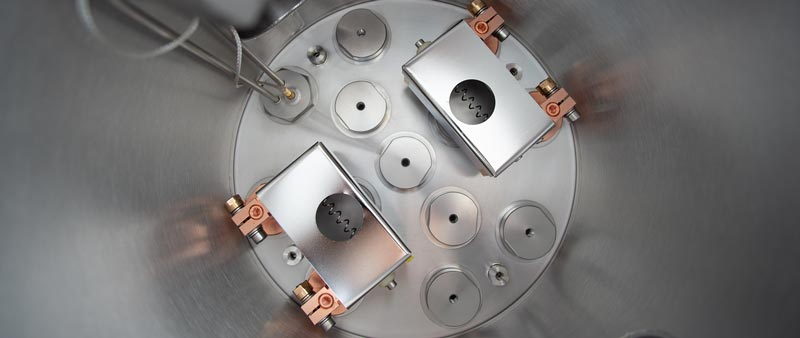

Electron-beam evaporation

Like all evaporative physical vapour deposition (PVD) methods, electron-beam evaporation (also known as e-beam evaporation) involves heating a material under vacuum conditions (typically in the 10-7 mbar region, or lower). This in-turn releases a vapour that moves up through a process chamber and coats a substrate at the top.