The team utilises a switching technology known as ‘Chirality-molecular-motors’ for developing these devices. The technology rotates propeller shaped molecules 360° in four steps using a combination of photochemical and thermal films. The group have published a paper on this topic in 2019 called “Light-driven molecular switch for reconfigurable spin filters” (Nature Communications; https://www.nature.com/articles/s41467-019-10423-6) when they were based at the Institute for Molecular Science, Japan.

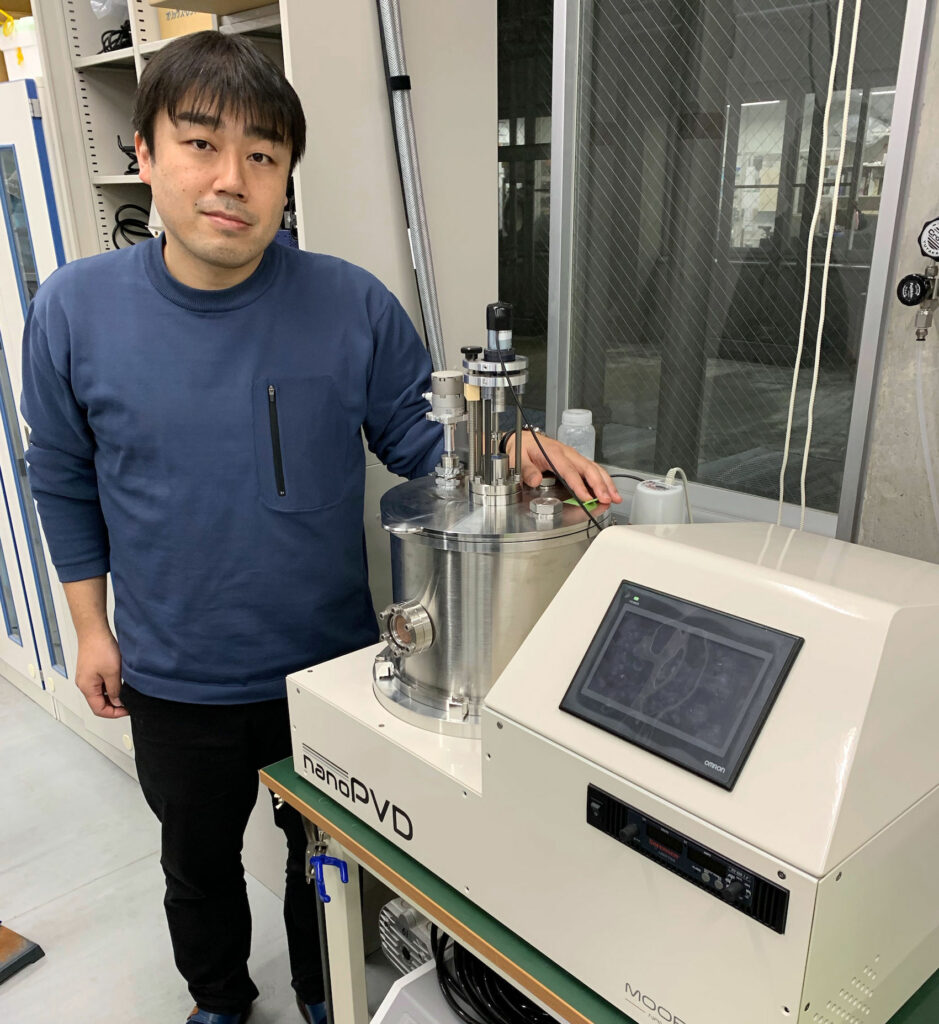

On moving to Kyoto University, Mr Suda and his group have been working on the development of next generation spintronics devices. Critical for this application is the creation of films containing materials with different characteristics — conductive, insulating and magnetic. The nanoPVD-S10A magnetron sputtering system was an ideal solution for this. The product can be equipped with up to 3 sources, allowing for deposition of multiple materials with different properties within a single process run. The unit is also available with RF and DC power supplies allowing for the deposition of both insulating and conductive materials.

We interviewed Mr Suda in his group’s laboratories at Kyoto University. He commented that tools on the market with the high-end capabilities required for his application are always large in form or requiring load-locks or multi-chamber platforms. Such systems come with large footprints and high pricing to match the extensive hardware needed. Instead, the nanoPVD-S10A system provided the perfect solution.

‘When I was making my plan for development two years ago, I was looking for a tool that was compact enough to fit in my limited space but that also came with a high-end specification in line with my research needs. The nanoPVD-S10A was the only choice.’,

he said.

‘As you can see in our laboratory, there are many tools in one room crowded together. The nanoPVD-S10A system sits within a small, compact space but still provides excellent performance.’

‘A compact, small footprint and high-performance are top priorities for research equipment for university laboratories. The nanoPVD-S10A is unique in meeting all these requirements.’

As well as being compact and with a high-end feature set, nanoPVD tools are designed to be easy to use. Students in Mr Suda’s group students found it easy to understand the control software for safe, straightforward operation. Mr Suda also noted that the systems come a wide range of available features including substrate rotation, precise gas and pressure control, manual or automatic control through a clear touchscreen HMI and multi0-layer process recipes. ‘This is the perfect choice for a University laboratory. People cannot believe that a feature set this rich would be available in such a compact, benchtop platform.’