Small Batch Coater

Scalable Thin-Film Deposition

Scalable Thin-Film Deposition for Startups & SMEs

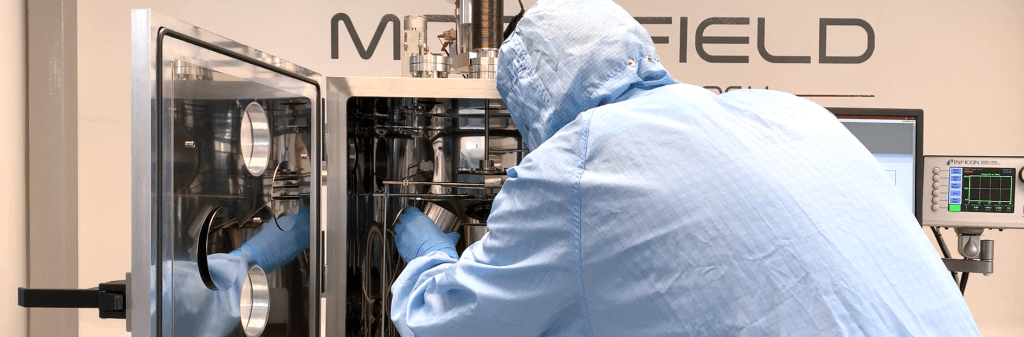

Our MiniLab PVD systems let startups and small enterprises scale from R&D to pilot production—without the cost or complexity of full industrial tools.

Compact and modular, each MiniLab delivers research-grade thin films on substrates up to 11″, with configurations for thermal evaporation, e-beam evaporation, and magnetron sputtering—all in one cleanroom-ready platform.

Key advantages:

-

Affordable & space-saving: Entry-level pricing, floor-standing footprint

-

Versatile: Metals, dielectrics, and organics in a single system

-

Scalable: Options for automation and load-locks to boost throughput

-

Precise: Exceptional film uniformity for semiconductors, optics, and advanced tech

With recipe-driven automation, users can run complex multi-layer processes at the touch of a button, ensuring repeatable results and opening the system to inexperienced users. Load-lock modules allow rapid sample changeovers without breaking vacuum, improving productivity and preserving film quality.

From electronic layers and optical coatings to emerging nanotech, MiniLab systems give you the flexibility to innovate faster—right in your own facility.

Example Options

Load Lock

Improve throughput and maintain the integrity of the main chamber with option to add substrate cleaning.

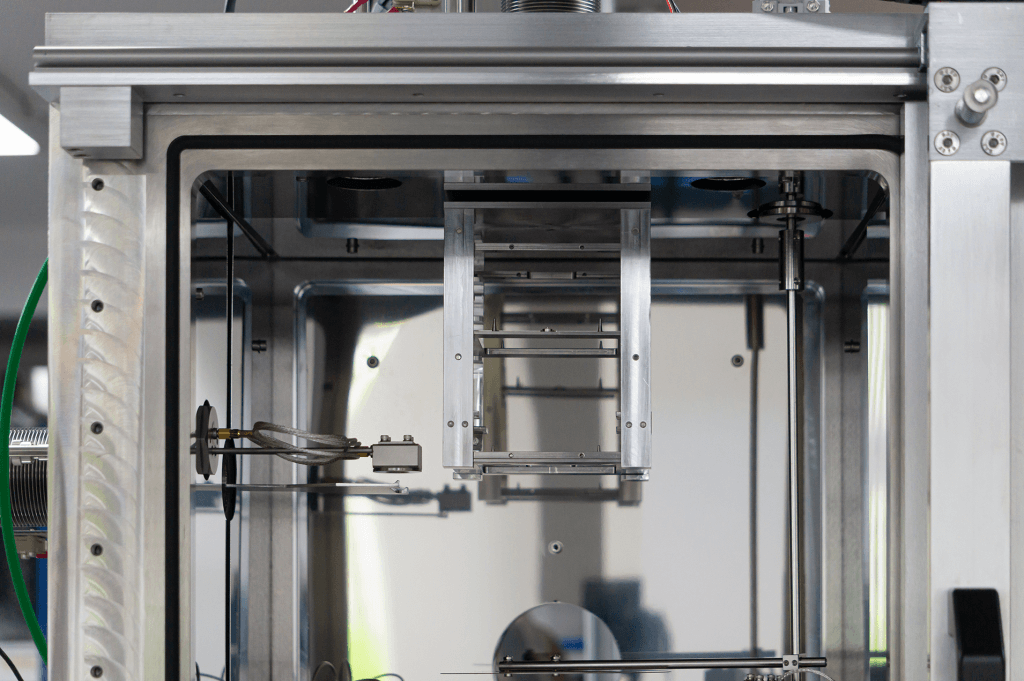

Automatic Substrate & Mask Control

Allows automatic positioning of up to five masks and substrates from parking positions into the deposition position. Allows small batch runs with high degree of repeatability.

Dual Chamber Options

Maximise system flexibility and throughput utilising a dual chamber design. Multiple process steps can be completed without exposing the substrates to atmosphere.

Key features

- Modular design

- Turbomolecular or cryo-pumping systems

- Base pressures <5 × 10-7 mbar

- Metals, dielectrics and organics deposition

- Up to 11” diameter substrates

- Touchscreen HMI/PC for system control

- Equipped for easy servicing

- Comprehensive safety features and interlocks

- Cleanroom compatible

Protect your investment and maximise uptime

Your Moorfield system is a long-term asset that needs to operate reliably and repeatably. A Service Plan is designed to protect your investment by reducing unplanned downtime, improving system reliability, and giving your team faster access to expert support when you need it.

Your Moorfield system is a long-term asset that needs to operate reliably and repeatably. A Service Plan is designed to protect your investment by reducing unplanned downtime, improving system reliability, and giving your team faster access to expert support when you need it.

All plans include an annual preventive maintenance visit (with documented checks) plus remote technical support—helpful for troubleshooting issues quickly without waiting for an on-site visit. As your needs increase, higher tiers add greater consumables/parts cover, discounted call-outs and travel, priority scheduling, and training refresher days to help new users get up to speed and reduce avoidable errors.

Service Plans also support easier budgeting (fixed annual or monthly options on eligible tiers) and provide multi-system discounts.

Ask us which plan best fits your throughput demands and budget priorities using our CONTACT US FORM