MiniLab 070

MiniLab 070 PVD systems have front-loading box-type chambers and are optimised for magnetron sputtering for substates up to 11″ diameter.

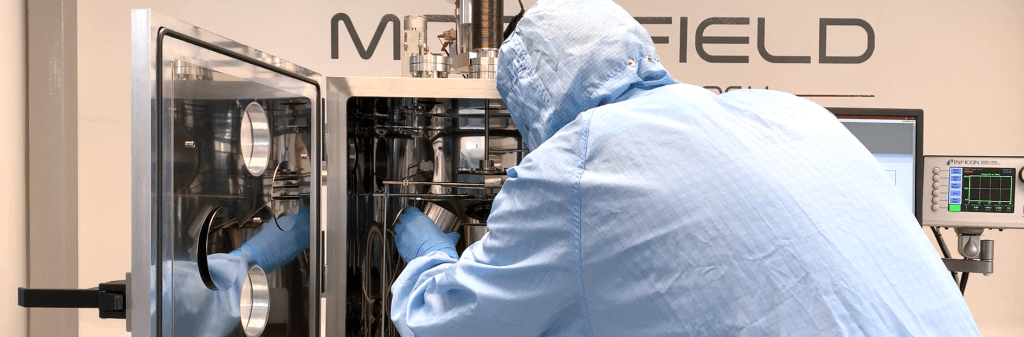

MiniLab 070 Modular PVD System

Optimised for magnetron sputtering for substrates up to 11″ diameter. The vacuum chamber sits on a double-rack frame that contains all system control electronics and power supplies.

Deposition sources are typically mounted on the chamber baseplate, but sputter-down configurations are also available.

Substrate stages, usually at the top of the chamber, can accommodate substrate sizes up to 11” diameter. Substrate heating, rotation, bias and Z-shift are available, together with planetary stages and source and substrate shutters. Configurations range from a manually operated thermal evaporation system up to a multi-technique tool with fully automated process control.

Key features

- Modular design

- Front-loading box-type vacuum chamber

- Turbomolecular and cryo pumping systems

- Base pressures <5 × 10-7 mbar

- Metals, dielectrics and organics deposition

- Up to 11” diameter substrates

- Up to 4 sources

- Touchscreen HMI/PC for system control

- Equipped for easy servicing

- Comprehensive safety features and interlocks

- Cleanroom compatible

- Load-locks available

Example MiniLab Publications

Options

- Pumping: Turbomolecular or cryogenic high-vacuum pumps, rotary or scroll backing pumps.

- Gas/pressure: Manual or automatic control via MFCs and throttle valves.

- Load-locks: Single- and multiple-sample.

- Stages: Rotation, heating, cooling, Z-shift, bias and planetary.

- Shutters: Source and substrate, pneumatic or motorised

- Operation: Manual or automatic via front panels, touchscreen HMI or PC.

- Process: Quartz crystal sensor heads for rate/thickness monitoring or feedback-loop control.

Example Configurations

System Images

Protect your investment and maximise uptime

All plans include an annual preventive maintenance visit (with documented checks) plus remote technical support—helpful for troubleshooting issues quickly without waiting for an on-site visit. As your needs increase, higher tiers add greater consumables/parts cover, discounted call-outs and travel, priority scheduling, and training refresher days to help new users get up to speed and reduce avoidable errors.

Service Plans also support easier budgeting (fixed annual or monthly options on eligible tiers) and provide multi-system discounts.

Ask us which plan best fits your throughput demands and budget priorities using our CONTACT US FORM