PVD techniques

Moorfield are experienced in all common PVD techniques and can supply systems with fully-integrated component sets. Standalone components also available.

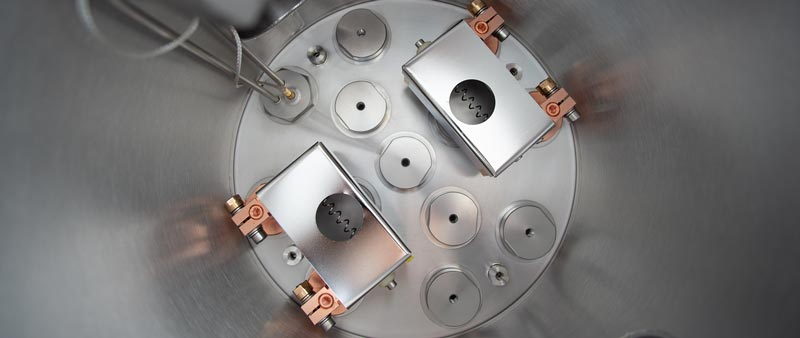

Magnetron sputtering

Magnetron sputtering is a versatile technique suited to a wide range of materials – and provides excellent coating-substrate adhesion.

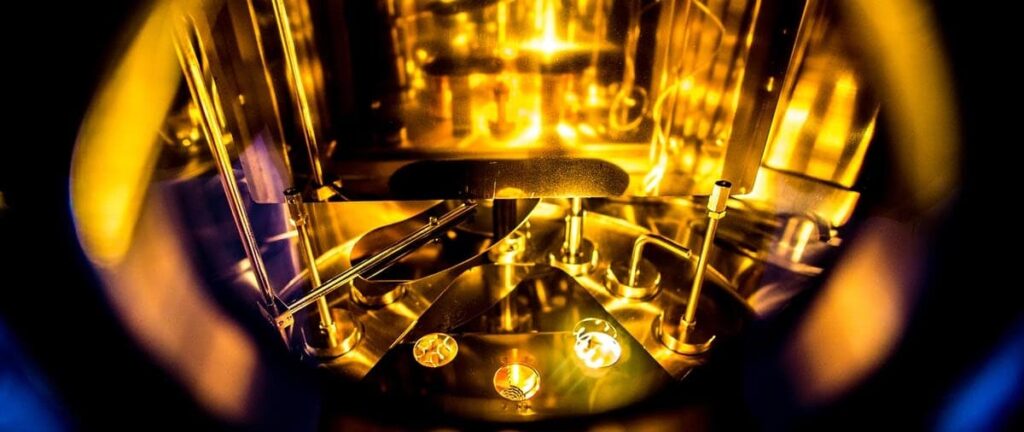

Low temperature evaporation

The basics of Vacuum Evaporation Low temperature evaporation is a recent development in the field of vacuum evaporation. Traditional vacuum evaporation methods work, essentially, by heating materials to high temperatures. This is required for common thin-film evaporants so that they are vapourised from a source. The evaporants then move up through a process chamber to […]

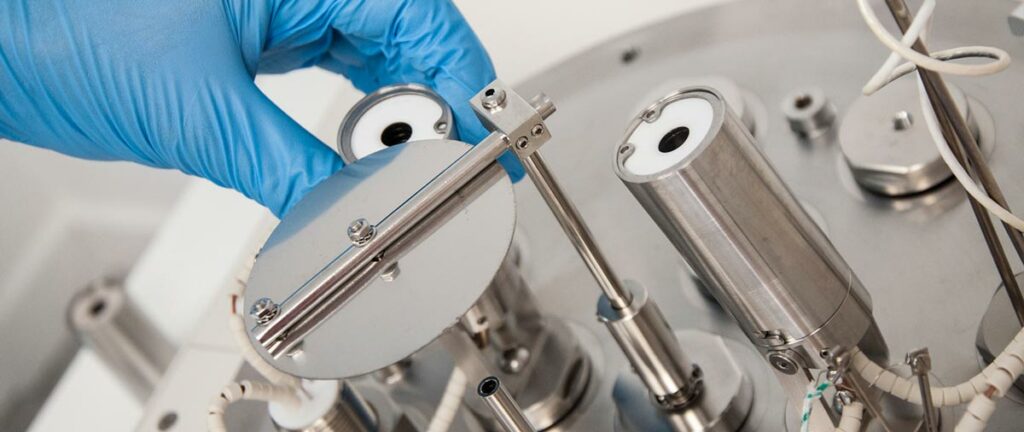

Thermal evaporation

Thermal evaporation is the most straightforward physical vapour deposition (PVD) technique, in terms of both mechanism and system configuration. The method is suitable for depositing a range of materials, primarily metals.

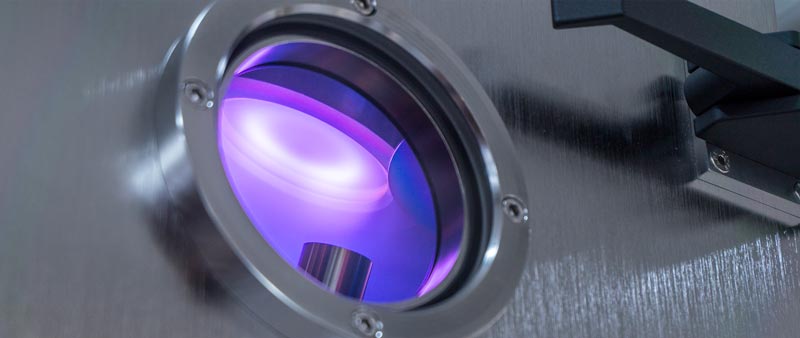

Electron-beam evaporation

Like all evaporative physical vapour deposition (PVD) methods, electron-beam evaporation (also known as e-beam evaporation) involves heating a material under vacuum conditions (typically in the 10-7 mbar region, or lower). This in-turn releases a vapour that moves up through a process chamber and coats a substrate at the top.